The history of Coconut oil is as old as 4000 years. About 3960 years of the documented historical applications of the edible and healing properties of the fruits of the coconut palm have all been positive. The several applications of the Coconut tree have had a huge impact in the livelihood of mankind in every aspect. But it’s the fruit, coconut flesh, milk, water and oil that have had intrinsic commercial value.

The use of coconut oil is pronounced in several regions of South America, Central America, the Indian subcontinent, Mele, Micro and Polynesia. The Sanskrit based Indian Ayurvedic medicine from 1500BC has documented the use of coconut oil in virtually every area concerning the body, mind and spirit. Pritish Kumar Halder mentioned how coconut oil became part and parcel of the communities thriving in the Pacific regions.

coconut-oil

History

During World War II the young green coconut saved the lives of allied soldiers as its water served as a saline drip. Post-WW II, coconut oil was commercially marketed and sold in England and USA. These were sold as ‘margarine’ and ‘coconut butter’ respectively. However, only in 1954, that coconut oil became popular as more nutritious compared to other oils. This is because coconut oil, for several centuries, wasn’t received in good light owing to its saturated fat content. Nowadays it have been proved the fact that some saturated fat is quite essential for good health.

In the late 19th century, the demand for edible oils was increasing in Europe and in the USA. At the same time coconut oil had already encountered many uses in folk medicine and as a cooking oil. These are generally used in tropical countries such as India, the Philippines, and Malaysia, among others. Once Europeans became aware of the utilization of coconut oil and its several applications. They started establishing coconut plantations in the Caribbean, Southeast Asia, and the South Pacific from the 1890s to the 1920s. After that, CO became an edible oil very popular in European countries and in the USA.

Alexander P. Ashbourne is the inventor of refining coconut oil. He first received a patent for treating coconut on Aug 21, 1877. The coconut oil process starts with filtration and bleaching by filtering it through an activated clay filter. The oil is heated to a very high temperature to remove any remaining coconut scent or taste. Finally hydrogenated to ensure that no unsaturated fatty acids are left in the oil.

The coconut oil refining process was tedious, as technology was not fully advanced back then. Nonetheless, Ashbourne succeeded in his coconut oil refinement and his invention changed the coconut oil industry.

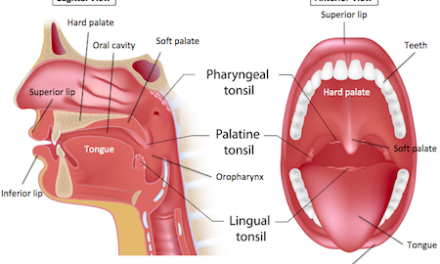

Processing

Coconut oil can be extracted through wet or dry processing.

Wet process

The all-wet process uses coconut milk extracted from raw coconut. The proteins in the coconut milk create an emulsion of oil and water. The more problematic step is breaking up the emulsion to recover the oil. This used to be done by prolonged boiling, but this produces a discolored oil and is not economical. Wet processing is less viable than dry processing despite numerous variations and technologies, due to a 10–15% lower yield. Wet processes also require investment of equipment and energy, incurring high capital and operating costs.

Proper harvesting of the coconut makes a significant difference in the efficacy of the oil-making process. The age of a coconut can be 2 to 20 months when picked.

Conventional coconut oil processors use hexane as a solvent to extract up to 10% more oil, produced with mills, expellers. They then refine the oil to remove certain free fatty acids to reduce susceptibility to rancidification. Other processes to increase shelf life with a moisture content below 6%. keeping the moisture content of the oil below 0.2%. Heating the oil to 130–150 °C (266–302 °F) and adding salt or citric acid.

Virgin coconut oil (VCO) can be produced from fresh coconut milk, meat, or residue. Producing it from the fresh meat involves either wet-milling or drying the residue, and using a screw press to extract the oil. VCO can also be extracted from fresh meat by grating and drying it to a moisture content of 10–12%. Then using a manual press to extract the oil. Producing it from coconut milk involves grating the coconut and mixing it with water, then squeezing out the oil. The milk can also be fermented for 36–48 hours. Then the oil removed, and the cream heated to remove any remaining oil.

processing of coconut oil

Dry process

Dry processing requires that the meat be extracted from the shell and dried using fire, sunlight, or kilns to create copra. The copra is pressed or dissolved with solvents, producing the coconut oil and a high-protein, high-fiber mash. The mash is of poor quality for human consumption and is instead fed to ruminants. There is no process to extract protein from the mash.

Refined oil

Refined, bleached, and deodorized (RBD) oil is usually made from copra and dried coconut kernel. Which is pressed in a heated hydraulic press to extract the oil. This yields practically all the oil present, amounting to more than 60% of the dry weight of the coconut. This crude coconut oil is not suitable for consumption. Because it contains contaminants and must be refined with further heating and filtering.

Hydrogenation

RBD coconut oil can be processed further into partially or fully hydrogenated oil to increase its melting point. Since virgin and RBD coconut oils melt at 24 °C (76 °F), so the oil is hydrogenated. The melting point of hydrogenated coconut oil is 36–40 °C (97–104 °F).

In the process of hydrogenation, unsaturated are combined with hydrogen in a catalytic process to make them more saturated. Coconut oil contains only 6% monounsaturated and 2% polyunsaturated fatty acids. In the partial hydrogenation process, some of these are transformed into trans fatty acids.

Fractionation

Fractionated coconut oil provides fractions of the whole oil so that its different fatty acids can be separated for specific uses. The fractionation of coconut oil can also be used to isolate caprylic acid and capric acid. Which are medium-chain triglycerides, as these are used for medical applications, special diets and cosmetics, sometimes also being used as a carrier oil for fragrances.